[Prev]

[Next]

Cozy MKIV - Chapter 18 (Section 1)

Building the Turtleback

Start Date: March 12, 1997

I decided to purchase the turtleback from Jeff Russell at Aerocad, to ensure a smooth outer surface and to

save a bit of time. When it arrived, I measured it and found that it was not as wide as

the plans specified. After some consultation with Jeff, during which he offered to replace

it, we decided to try to expand it by heating. I wedged some 1 x 2's into the front and

rear of the TB, placed the whole thing in the cardboard shipping box in which it had come,

and pointed a 1500 Watt space heater into it. After a couple of hours, the temperature

stabilized at approximately 120 degrees F and a couple more hours at temperature, with a

couple of hours cool down had expanded it to the correct size, saving me time and money

for shipping a replacement.

Except for the fact that the turtleback doesn't have

the correct recess in it between the window areas for the lap joint where it opens and

it's about 3/8" short (easily dealt with by placing 3/8" foam under the

flanges), the quality seems very good.

Except for the fact that the turtleback doesn't have

the correct recess in it between the window areas for the lap joint where it opens and

it's about 3/8" short (easily dealt with by placing 3/8" foam under the

flanges), the quality seems very good.

I began by cutting out the foam for the TB bulkhead from scraps of 3/8" foam and

then laid up both sides with BID and peel ply. I trimmed the TB to length (46") and

marked the inside of the TB for the future cut line. I drilled 1/8" holes to mark the

line. I then cut foam for the drip rail, hot glued it in place, and covered it with box

sealing tape. I glassed the TB bulkhead in place, and also glassed over the drip rail

foam.

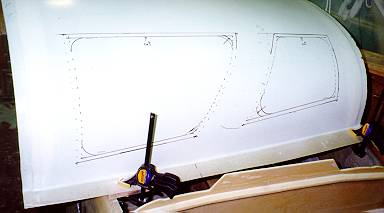

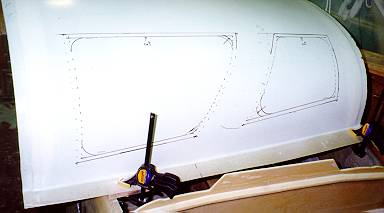

After flipping the TB, I began marking and cutting out the window

frames and windows until I had a good fit for all four. Then I floxed the windows in

place, holding them in with wedges. I finished the inside frames with the BID layups, and

then SprayLat'ed the outside of the windows to protect them.

After flipping the TB, I began marking and cutting out the window

frames and windows until I had a good fit for all four. Then I floxed the windows in

place, holding them in with wedges. I finished the inside frames with the BID layups, and

then SprayLat'ed the outside of the windows to protect them.

Next, I cut the canopy hinges to length and floxed them to the

fuselage longerons. This photograph illuminates the scintillating use of a 6 foot spruce

straightedge and saran wrap to perform this activity.

Next, I cut the canopy hinges to length and floxed them to the

fuselage longerons. This photograph illuminates the scintillating use of a 6 foot spruce

straightedge and saran wrap to perform this activity.

I fitted the TB and upper firewall in place on the

fuselage rear, ensuring that the upper firewall was perfectly vertical and in line with

the lower firewall. I shimmed the TB to the correct height in the rear, and shimmed it

about 1" higher in the front to accommodate the slightly larger canopy and give a bit

more headroom. I drilled positioning holes through the flanges and the longerons, and use

AN3 bolts to hold the TB in perfect alignment. I then glassed 2 BID tape on the exterior

of the TB and firewall to hold the upper firewall to the TB rear. I'll do the interior

tape when the TB comes off later.

I fitted the TB and upper firewall in place on the

fuselage rear, ensuring that the upper firewall was perfectly vertical and in line with

the lower firewall. I shimmed the TB to the correct height in the rear, and shimmed it

about 1" higher in the front to accommodate the slightly larger canopy and give a bit

more headroom. I drilled positioning holes through the flanges and the longerons, and use

AN3 bolts to hold the TB in perfect alignment. I then glassed 2 BID tape on the exterior

of the TB and firewall to hold the upper firewall to the TB rear. I'll do the interior

tape when the TB comes off later.

End Date: April 5, 1997

Addendum:

Start Date: January 8, 1999

Well,

after a LONG wait, I finished the main spar attachment and the strakes. I began the

attachment of the turtleback to the fuselage by ensuring that it (and the canopy) still

fit on the fuselage and to each other. Since they did, I cut the BID strips for the

TB/Fuselage inside and outside layups, as well as the TB/Spar layups. I used a bit

of pour foam to fill the space between the TB and the longerons (since I had increased the

height of the front of the TB by about 1/2" for more headroom), and then floxed the

TB to the longerons. I then glassed the 3 layers of TB/Spar layups and the inside

and outside TB/Fuselage layups. You can see the result in the image to the left:

Well,

after a LONG wait, I finished the main spar attachment and the strakes. I began the

attachment of the turtleback to the fuselage by ensuring that it (and the canopy) still

fit on the fuselage and to each other. Since they did, I cut the BID strips for the

TB/Fuselage inside and outside layups, as well as the TB/Spar layups. I used a bit

of pour foam to fill the space between the TB and the longerons (since I had increased the

height of the front of the TB by about 1/2" for more headroom), and then floxed the

TB to the longerons. I then glassed the 3 layers of TB/Spar layups and the inside

and outside TB/Fuselage layups. You can see the result in the image to the left:

I cut the glass and layed up the 5 BID

outside top engine mount reinforcing layups and the 8 BID inside engine mount reinforcing

layups. After this, I cut a piece of 1/4" foam to fit over the main spar center

area and fitted the two center plywood sections of the firewall to the spar/TB/firewall

area. I then floxed and glassed these in place with 1 BID per plans.

I cut the glass and layed up the 5 BID

outside top engine mount reinforcing layups and the 8 BID inside engine mount reinforcing

layups. After this, I cut a piece of 1/4" foam to fit over the main spar center

area and fitted the two center plywood sections of the firewall to the spar/TB/firewall

area. I then floxed and glassed these in place with 1 BID per plans.

End Date: January 24, 1999

[Prev]

[Next]

Copyright © 1997, 2000, All Rights Reserved, Marc J. Zeitlin

email: marc_zeitlin@alum.mit.edu

Except for the fact that the turtleback doesn't have

the correct recess in it between the window areas for the lap joint where it opens and

it's about 3/8" short (easily dealt with by placing 3/8" foam under the

flanges), the quality seems very good.

Except for the fact that the turtleback doesn't have

the correct recess in it between the window areas for the lap joint where it opens and

it's about 3/8" short (easily dealt with by placing 3/8" foam under the

flanges), the quality seems very good. After flipping the TB, I began marking and cutting out the window

frames and windows until I had a good fit for all four. Then I floxed the windows in

place, holding them in with wedges. I finished the inside frames with the BID layups, and

then SprayLat'ed the outside of the windows to protect them.

After flipping the TB, I began marking and cutting out the window

frames and windows until I had a good fit for all four. Then I floxed the windows in

place, holding them in with wedges. I finished the inside frames with the BID layups, and

then SprayLat'ed the outside of the windows to protect them. Next, I cut the canopy hinges to length and floxed them to the

fuselage longerons. This photograph illuminates the scintillating use of a 6 foot spruce

straightedge and saran wrap to perform this activity.

Next, I cut the canopy hinges to length and floxed them to the

fuselage longerons. This photograph illuminates the scintillating use of a 6 foot spruce

straightedge and saran wrap to perform this activity. I fitted the TB and upper firewall in place on the

fuselage rear, ensuring that the upper firewall was perfectly vertical and in line with

the lower firewall. I shimmed the TB to the correct height in the rear, and shimmed it

about 1" higher in the front to accommodate the slightly larger canopy and give a bit

more headroom. I drilled positioning holes through the flanges and the longerons, and use

AN3 bolts to hold the TB in perfect alignment. I then glassed 2 BID tape on the exterior

of the TB and firewall to hold the upper firewall to the TB rear. I'll do the interior

tape when the TB comes off later.

I fitted the TB and upper firewall in place on the

fuselage rear, ensuring that the upper firewall was perfectly vertical and in line with

the lower firewall. I shimmed the TB to the correct height in the rear, and shimmed it

about 1" higher in the front to accommodate the slightly larger canopy and give a bit

more headroom. I drilled positioning holes through the flanges and the longerons, and use

AN3 bolts to hold the TB in perfect alignment. I then glassed 2 BID tape on the exterior

of the TB and firewall to hold the upper firewall to the TB rear. I'll do the interior

tape when the TB comes off later. Well,

after a LONG wait, I finished the main spar attachment and the strakes. I began the

attachment of the turtleback to the fuselage by ensuring that it (and the canopy) still

fit on the fuselage and to each other. Since they did, I cut the BID strips for the

TB/Fuselage inside and outside layups, as well as the TB/Spar layups. I used a bit

of pour foam to fill the space between the TB and the longerons (since I had increased the

height of the front of the TB by about 1/2" for more headroom), and then floxed the

TB to the longerons. I then glassed the 3 layers of TB/Spar layups and the inside

and outside TB/Fuselage layups. You can see the result in the image to the left:

Well,

after a LONG wait, I finished the main spar attachment and the strakes. I began the

attachment of the turtleback to the fuselage by ensuring that it (and the canopy) still

fit on the fuselage and to each other. Since they did, I cut the BID strips for the

TB/Fuselage inside and outside layups, as well as the TB/Spar layups. I used a bit

of pour foam to fill the space between the TB and the longerons (since I had increased the

height of the front of the TB by about 1/2" for more headroom), and then floxed the

TB to the longerons. I then glassed the 3 layers of TB/Spar layups and the inside

and outside TB/Fuselage layups. You can see the result in the image to the left: I cut the glass and layed up the 5 BID

outside top engine mount reinforcing layups and the 8 BID inside engine mount reinforcing

layups. After this, I cut a piece of 1/4" foam to fit over the main spar center

area and fitted the two center plywood sections of the firewall to the spar/TB/firewall

area. I then floxed and glassed these in place with 1 BID per plans.

I cut the glass and layed up the 5 BID

outside top engine mount reinforcing layups and the 8 BID inside engine mount reinforcing

layups. After this, I cut a piece of 1/4" foam to fit over the main spar center

area and fitted the two center plywood sections of the firewall to the spar/TB/firewall

area. I then floxed and glassed these in place with 1 BID per plans.