[Prev][Next]

Cozy MKIV - Chapter 10

Building the Canard

Start Date: May 30, 1995

I decided to make the hot wire templates out of 1/16" aluminum. I used 3M

spray adhesive #77 to glue the paper templates to the aluminum, and then

carefully cut them out to within 1/32" of the line with a bandsaw. I used

a 1" belt sander to sand the rest of the shape, and files what I couldn't

sand. I made the straight cut templates out of 1/8" masonite. I convinced

my wife, Deanie, to assist in the hot-wiring, and we practiced making the

straight cuts to get the core trapezoids.

I decided to make the hot wire templates out of 1/16" aluminum. I used 3M

spray adhesive #77 to glue the paper templates to the aluminum, and then

carefully cut them out to within 1/32" of the line with a bandsaw. I used

a 1" belt sander to sand the rest of the shape, and files what I couldn't

sand. I made the straight cut templates out of 1/8" masonite. I convinced

my wife, Deanie, to assist in the hot-wiring, and we practiced making the

straight cuts to get the core trapezoids.

After a few cuts, we had the cut speed nailed, and proceeded to the

actual core cuts with real templates. Turns out my wife is a hot-wire

PRO! The most important thing in hot-wiring, IMHO, is fine motor skills;

i.e. keep a heavy thing moving slowly at a constant rate. Our cores

looked primo! Here they are (after all cuts, including the shear web

separation):

After a few cuts, we had the cut speed nailed, and proceeded to the

actual core cuts with real templates. Turns out my wife is a hot-wire

PRO! The most important thing in hot-wiring, IMHO, is fine motor skills;

i.e. keep a heavy thing moving slowly at a constant rate. Our cores

looked primo! Here they are (after all cuts, including the shear web

separation):

Next, I riveted the nutplates onto the shear web 1/8" aluminum inserts

(from Brock MFG). After test jigging the rear canard cores vertically

in between two 2" x 4" 's, I held everthing in place with nails,

micro'ed the left and right cores to the center core, and then used a

couple of templates to locate and micro the inserts into the center

core. I then masked the bottom of the cores with tape so that epoxy

wouldn't drip on it, and glassed the shear web. Here's the finished

web:

Next, I riveted the nutplates onto the shear web 1/8" aluminum inserts

(from Brock MFG). After test jigging the rear canard cores vertically

in between two 2" x 4" 's, I held everthing in place with nails,

micro'ed the left and right cores to the center core, and then used a

couple of templates to locate and micro the inserts into the center

core. I then masked the bottom of the cores with tape so that epoxy

wouldn't drip on it, and glassed the shear web. Here's the finished

web:

Once that was done, I drilled out the 1/4" holes for the alignment

dowels and the insert nutplates, jigged the cores with the bottom side

up, made sure the front cores fit in place, and then hot glued all the

rear cores to the support templates, making sure they were straight and

level.

Once that was done, I drilled out the 1/4" holes for the alignment

dowels and the insert nutplates, jigged the cores with the bottom side

up, made sure the front cores fit in place, and then hot glued all the

rear cores to the support templates, making sure they were straight and

level.

I then micro'ed the front cores to the rear cores, using the dowels for

alignment. I micro'ed the spar cap corner radii, as well as any dings

and dents in the foam. I layed up the bottom spar cap, staggering and

tapering the ends of the 3" wide unidirectional tape. I used 9 layers

of the tape, and filled the spar cap trough to the top. The preparation

for the layup looked like:

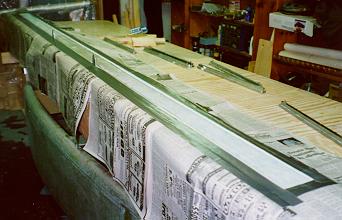

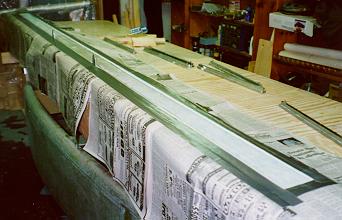

Then I glassed the UNI/BID/UNI bottom canard skin. Here's the bottom

layup under peel-ply:

Then I glassed the UNI/BID/UNI bottom canard skin. Here's the bottom

layup under peel-ply:

After sanding the bottom skin smooth, I hot glued 1-1/4" PVC drain pipe

to the canard elevator recess, mounted five 1" x 4" x 8" wood jigs to

the canard, and flipped the whole thing to work on the top of it. I

then made the PVC foam hinge mount points, hollowed out spaces for them

in the foam, and micro'ed them in place. I also micro'ed the spar cap

radii (and dents and dings in the foam). Next, I layed up the top spar

cap, using the same technique as for the bottom. Tapering the end

cuts of the 3" wide spar cap tape is critical! (As it was for the

bottom cap). It allows the end of each layer to blend into the previous

layer without ANY bump or joggle. Nat doesn't stress this enough in the

plans.

After sanding the bottom skin smooth, I hot glued 1-1/4" PVC drain pipe

to the canard elevator recess, mounted five 1" x 4" x 8" wood jigs to

the canard, and flipped the whole thing to work on the top of it. I

then made the PVC foam hinge mount points, hollowed out spaces for them

in the foam, and micro'ed them in place. I also micro'ed the spar cap

radii (and dents and dings in the foam). Next, I layed up the top spar

cap, using the same technique as for the bottom. Tapering the end

cuts of the 3" wide spar cap tape is critical! (As it was for the

bottom cap). It allows the end of each layer to blend into the previous

layer without ANY bump or joggle. Nat doesn't stress this enough in the

plans.

Next, I glassed the UNI/BID/UNI/UNI top skin, and filled the low spots

with dry micro. Here's the canard on the bench after glassing the top

skin (and applying some micro):

Here's the raw glassed and partially micro'ed canard hanging in what

will be its resting place for the next year or so (after I finish

Chapter 12):

Here's the raw glassed and partially micro'ed canard hanging in what

will be its resting place for the next year or so (after I finish

Chapter 12):

End Date: July 10, 1995

[Prev][Next]

Copyright © 1995, 1996, All Rights Reserved, Marc J. Zeitlin

After a few cuts, we had the cut speed nailed, and proceeded to the

actual core cuts with real templates. Turns out my wife is a hot-wire

PRO! The most important thing in hot-wiring, IMHO, is fine motor skills;

i.e. keep a heavy thing moving slowly at a constant rate. Our cores

looked primo! Here they are (after all cuts, including the shear web

separation):

After a few cuts, we had the cut speed nailed, and proceeded to the

actual core cuts with real templates. Turns out my wife is a hot-wire

PRO! The most important thing in hot-wiring, IMHO, is fine motor skills;

i.e. keep a heavy thing moving slowly at a constant rate. Our cores

looked primo! Here they are (after all cuts, including the shear web

separation): I decided to make the hot wire templates out of 1/16" aluminum. I used 3M

spray adhesive #77 to glue the paper templates to the aluminum, and then

carefully cut them out to within 1/32" of the line with a bandsaw. I used

a 1" belt sander to sand the rest of the shape, and files what I couldn't

sand. I made the straight cut templates out of 1/8" masonite. I convinced

my wife, Deanie, to assist in the hot-wiring, and we practiced making the

straight cuts to get the core trapezoids.

I decided to make the hot wire templates out of 1/16" aluminum. I used 3M

spray adhesive #77 to glue the paper templates to the aluminum, and then

carefully cut them out to within 1/32" of the line with a bandsaw. I used

a 1" belt sander to sand the rest of the shape, and files what I couldn't

sand. I made the straight cut templates out of 1/8" masonite. I convinced

my wife, Deanie, to assist in the hot-wiring, and we practiced making the

straight cuts to get the core trapezoids. Next, I riveted the nutplates onto the shear web 1/8" aluminum inserts

(from Brock MFG). After test jigging the rear canard cores vertically

in between two 2" x 4" 's, I held everthing in place with nails,

micro'ed the left and right cores to the center core, and then used a

couple of templates to locate and micro the inserts into the center

core. I then masked the bottom of the cores with tape so that epoxy

wouldn't drip on it, and glassed the shear web. Here's the finished

web:

Next, I riveted the nutplates onto the shear web 1/8" aluminum inserts

(from Brock MFG). After test jigging the rear canard cores vertically

in between two 2" x 4" 's, I held everthing in place with nails,

micro'ed the left and right cores to the center core, and then used a

couple of templates to locate and micro the inserts into the center

core. I then masked the bottom of the cores with tape so that epoxy

wouldn't drip on it, and glassed the shear web. Here's the finished

web: Once that was done, I drilled out the 1/4" holes for the alignment

dowels and the insert nutplates, jigged the cores with the bottom side

up, made sure the front cores fit in place, and then hot glued all the

rear cores to the support templates, making sure they were straight and

level.

Once that was done, I drilled out the 1/4" holes for the alignment

dowels and the insert nutplates, jigged the cores with the bottom side

up, made sure the front cores fit in place, and then hot glued all the

rear cores to the support templates, making sure they were straight and

level. Then I glassed the UNI/BID/UNI bottom canard skin. Here's the bottom

layup under peel-ply:

Then I glassed the UNI/BID/UNI bottom canard skin. Here's the bottom

layup under peel-ply: After sanding the bottom skin smooth, I hot glued 1-1/4" PVC drain pipe

to the canard elevator recess, mounted five 1" x 4" x 8" wood jigs to

the canard, and flipped the whole thing to work on the top of it. I

then made the PVC foam hinge mount points, hollowed out spaces for them

in the foam, and micro'ed them in place. I also micro'ed the spar cap

radii (and dents and dings in the foam). Next, I layed up the top spar

cap, using the same technique as for the bottom. Tapering the end

cuts of the 3" wide spar cap tape is critical! (As it was for the

bottom cap). It allows the end of each layer to blend into the previous

layer without ANY bump or joggle. Nat doesn't stress this enough in the

plans.

After sanding the bottom skin smooth, I hot glued 1-1/4" PVC drain pipe

to the canard elevator recess, mounted five 1" x 4" x 8" wood jigs to

the canard, and flipped the whole thing to work on the top of it. I

then made the PVC foam hinge mount points, hollowed out spaces for them

in the foam, and micro'ed them in place. I also micro'ed the spar cap

radii (and dents and dings in the foam). Next, I layed up the top spar

cap, using the same technique as for the bottom. Tapering the end

cuts of the 3" wide spar cap tape is critical! (As it was for the

bottom cap). It allows the end of each layer to blend into the previous

layer without ANY bump or joggle. Nat doesn't stress this enough in the

plans. Here's the raw glassed and partially micro'ed canard hanging in what

will be its resting place for the next year or so (after I finish

Chapter 12):

Here's the raw glassed and partially micro'ed canard hanging in what

will be its resting place for the next year or so (after I finish

Chapter 12):