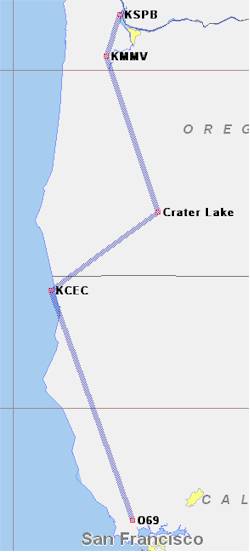

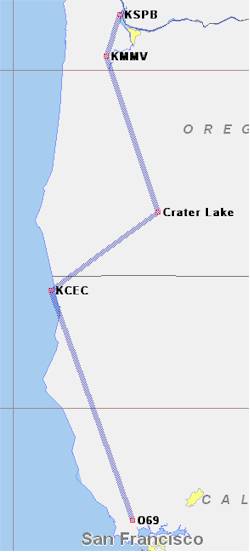

A sightseeing day here - heading north out of Petaluma, CA (O69), I'll head up to Crescent City, CA (KCEC), and then on to Crater Lake, OR to fly around the crater a bit. I'll then head up to McMinnville, OR (KMMV) to see the "Spruce Goose", which they've got in a museum there. In McMinnville I'll see Perry Mick and his ducted fan L.E., as well as some friends from work.

From McMinnville, it's a short hop up to Scappoose Industrial Park, OR (KSPB), where Al Wick and his Subaru powered COZY MKIV is located.

By this time, I should have gaggles of COZY's with me - Curt Smith, Brian Deford, Paul Stowitts, and Doug Pitzer :-).

Depending upon the time, I'll either stay overnight with Al, or head up north

to the Seattle area to catch up to Eric Westland, bringing the whole

bunch along with me, including Al :-).

Jim and I had some breakfast and headed out to the airport (notice a pattern here?). I began by trimming and sanding all of yesterday's layups while we waited for Nick Ugolini to arrive with the Nose Lift parts.

Let me tell you something - I've built two airplanes using all sorts of tools, but if I were ever to build another composite aircraft, the first thing I'd buy is one of those "Fein" sanders. Jim's got one, and it's the best thing since sliced bread. I figured that the trimming and sanding would take two or three hours - it took ONE. I kid you not, if I had had one while building the COZY, I'd have spent at least 100 hours less sanding and cutting than I actually did. Great stuff. Jim went home to do some errands while I worked on the plane

So everything was pretty much trimmed and sanded, and I was in the process of opening up the holes that I'd glassed over, when Dave Teter (a previous owner of a Velocity, and a COZY plans owner) drove up. Dave lives a half hour drive away from Jim, and apparently had called Jim to say he was coming over, but Jim never told me :-). I put Dave to work checking out the left wheel pant (it was loose from having weight put on it when we pushed the plane off of the runway onto the grass for a few minutes. After finding that tightening a couple of bolts fixed it, he went to work looking at the main gear attachment points (there was a very small stress crack in the fuselage skin layups just forward of the strut). He couldn't find (and neither could I) any problems with the gear or gear bulkheads - it looks as though the gear just moved forward enough to whack the skin in that area, but there's no meaningful structure there, at least in the skin.

While that was going on, and I was working on the nose, Jim came back and Nick arrived with the replacement Nose Lift strut tube. Jim and Nick went to work swapping tubes from my Nose Lift, while I readied the nose for the installation. We spent the next few hours installing the mechanism, testing it, adjusting limit switches, and checking fit. We also removed the NG-4 and ground down some of the strut to install a new NG-4 so that the new NL tube wouldn't have to be modified as mine was, to make it fit. It was during this work that I noticed that in fact, the backing plate for NG-6 (don't remember it's designation, but it's the thick aluminum plate that's got the 4 flathead screws holding NG-6 on) had been ground more than 1/2 away - that's probably why the hockey puck was still 1/2 there. The forward two screws were still intact, but the rear ones had their heads ground off (and were obviously performing no further work).

Jim, Nick and I went out to lunch (Dave went home), and then Nick took off on the rest of his business trip, leaving Jim and I to continue. Jim and I removed the two useless screws and replaced them (after some discussion about what type of screws would be appropriate, since we couldn't get AN hardware for them - I'll replace them with AN hardware ASAP, but I feel comfortable with the ones that are in there that will be part of my preflight until they're replaced).

I then started the rudder pedal reinstallation. This was a bear, since the pedals were VERY slightly bent, so even with the new connector tubes (which Steve Wright had brought), it was difficult to get the pedals to rotate freely. Eventually, with a lot of tube grinding, internal tube grinding, tube shortening, and gnashing of teeth, we got both sets of pedals working correctly with the right amount of rudder movement, as well as full brake operation. I will install a "keeper" to ensure that even if the rudder pedal is pulled forward, it CAN'T disengage the brake master cylinder actuator rod.

Next, I reinstalled all the wiring harness holders and the nose gear cover, and then Jim and I reinstalled the canard. This all had taken about 9 hours of work, with a lot of help from other folks. However, I think that I'm about 98% done. Tomorrow morning I just need to finish hooking up the canard bits and fix a few pop rivets on the engine baffling that I noticed when the cowling was off in Blacksburg, VA. Then it's up for a short test flight, and then finally, a trip to St. Louis to visit with Chrissi and Randi.

Once again, I could not have done any of this without the help of MANY people. Today, it was Jim (of course), Jack Wilhelmson (from afar), Nick Ugolini and Dave Teter. Jim has patiently put up with me knowing everything (or at least thinking I do), and even after four days of imposing on Jim and his wife Milene, they are nothing if not hospitable and good natured.

Thanks to all for jobs well done - I'm almost there :-).

| [Zeitlin's Cozy MKIV Information] [Zeitlin's Cozy MKIV Logbook] [Cozy MKIV Information] |

Copyright © 2004, All Rights Reserved, Marc J. Zeitlin