[Newsletters]

[Cozy MKIV Information]

COZY NEWSLETTER #56

January, 1997

Table Of Contents |

|

Newsletter Info.

Subscription Info.

Authorized Suppliers

OBSOLETE PLANS

This is a reminder that your plans are obsolete, unless you are current in your newsletter subscription and have made all of the corrections to your plans which have been published in the newsletter. We recently sent out a special advisory on canard incidence to all 500 builders who had purchased 1st edition plans. Of these, at least 100 were not current in their newsletter subscription, and quite a few had moved with either no forwarding address or forwarding had expired, and their notices were returned to us undelivered. We are doing the best we can to provide builders with the support we think is necessary for them to build good airplanes and fly safely, but we do need their cooperation.

COPPERSTATE EAA FLY-IN (MESA, AZ)

The 25th annual Arizona Copperstate regional EAA fly-in was held Oct. 10 - 13 at our huge Williams Gateway Airport. Temperatures were in the 90 - 100 deg. range with calm winds and hundred mile visibility. A record 490 show planes registered and there were 250 factory-built planes as well. Attendance was approximately 20,000.

There were 3 Cozy IIIs and 3 Cozy Mark IVs (one was highly modified) in attendance. We had a tent with a swamp cooler (courtesy of builder Ed Nielander), so it was a popular hangout for Cozy builders. We had a nice dinner on Friday evening at the Red Mountain Steak House and everyone had a good time. Alex Strong had a demonstration mock-up of his electric pitch trim, based on a Black and Decker electric screw driver, which attracted a lot of interest. On the last day we did a fly-by just off the deck in excess of 200 mph which people seemed to enjoy. We hope more Cozys can attend next year.

UP-DATE ON THE FRANKLIN

The good news is that our evaluation of the Franklin engine is essentially complete. We have just over 40 hrs. on it now. It first flew in June of 1996. After about 6 hrs. of local testing, we left on our annual fly-in tour, first to Arlington, WA, and then to Oshkosh via the Twin Cities. It has been very smooth running and reliable, taking us over the mountains a number of times. We made a trip to Page, AZ in September, and then a local cross country to Williams Gateway for the Copper State fly-in, and a number of demo flights since. The cylinder cooling was brought well under control by recontouring the top cowlings to increase the cowling outlet area. We have evaluated two different oil cooling systems. With a separate, dedicated scoop under the strake, we were able to cool to the 180 to 200 deg. range with a single 13 row cooler. Without the extra scoop, just using cowling air, it took two coolers to get down to the same 180 200 deg. range. This is because the airflow to the cooler is less direct and more obstructed using air from inside the cowling. With the same 3-bladed propeller we used on the Lycoming 0-360, i.e. 64 dia x 76 pitch, we get about the same static rpm. At full throttle at altitude we get about 2870 rpm and about 228 mph TAS. With a new 64 dia x 78 pitch prop, the same one Performance sells for the 200 hp IO-360, we get about 2350 static and 2750 rpm top end for about the same TAS. At full throttle, the Franklin is about 10 mph faster than the 0-360. So it seems to provide about the same power as the IO-360.

The bad news is our Franklin installation seems to be about 90 pounds heavier than the Lycoming 0-360, and maybe 50 Ibs heavier than the IO-360. We did an accurate weight and balance on 10/23/96. Empty weight of N14CZ has grown to 1192 Ibs. This is about 100 Ibs. more than the last weighing, of which about 90 Ibs. is probably due to the change of engines. The empty c.g. turned out to be F.S. 114.66. I have been flying solo with 45 Ibs. of lead in the ballast compartment and 42 Ibs. of lead forward of the rudder pedals. This puts me at a c.g. of 101.9 (barely inside the range) with half fuel. It also means that when I fly with Shirley (together we weigh 300 Ibs.), we need to carry 25 Ibs. of lead in the ballast compartment to put us inside the c.g. range. I had been using what I thought was extra ballast until I was through making changes and could do an accurate weight and balance, but it fumed out to just barely enough. The 90 extra Ibs. of engine plus 25 Ibs. of ballast equates to one light passenger, in exchange for a little more hp and a little more speed. For us, we don't believe it is worth it. We have, in our hangar, a 180 hp Lycoming 0-360, which we purchased in 1991 for $5500 with 1540 hrs since new, which now has 1820 hrs since new and might be good for another 500 hrs, or 4 or 5 years of flying. I like light airplanes, so we plan to put the Lycoming back in.

This has been an expensive experiment. We spent over $15,000 on this project, not counting R & D time (the first time you do something its always more expensive). We didn't do it for ourselves, because we were happy with our Lycoming, but we have been under this continuous pressure to suggest some alternate engine possibilities. We considered the Franklin to be the most promising substitution, but it has turned out to be heavier (installed) than we expected. The extra engine weight could be offset by a heavier front seat weight, or by locating the battery in the nose, but we will not recommend it for the average builder, and do not want to set a bad example by continuing to use it in our Mark IV.

If, in spite of our not recommending it, there are builders who still want to use the Franklin, let us know so we can make arrangements for cowlings and engine mounts before we dispose of ours.

OTHER ENGINE OPTIONS

The last time we talked to Superior, they were still at least a year away from having a Lycoming engine kit available, and it sounded like the cost would be higher than originally hoped.

We did, however, pick up some interesting news in the last General Aviation News & Flyer: "Teledyne Continental Motors (TCM) won a $9.5 million federal grant to develop a new diesel aircraft engine that will be cheaper to buy, cheaper to fly and easier to operate than anything else in general aviation. Designed to be test flown within three years and in production in six, the new engine will run on jet fuel and promises to be a vast improvement over the traditional, gasoline-powered, spark ignition engines that now power most private aircraft. TCM's proposal to develop a 200 hp. two-cycle, direct-injection, horizontally opposed, compression-ignition engine was selected over seven competing proposals for the NASA grant. TCM is proposing to have its new diesel engine flying on an entry-level GA aircraft by the end of 1999." Wouldn't this be a great engine for the Cozy!!!

ACCIDENTS

The purpose in investigating and reporting on accidents is to try to identify the cause, and then take whatever action that seems to be appropriate to prevent it from occurring again. We have two non-fatal accidents to report:

- We were following the saga of Merle Musson's 3-place Cozy. His was one of the first

completed. He first had an 0-235 Lycoming, and later installed a Blanton Ford V-6. A few

years ago he put it up for sale at Sun 'n Fun, and it was purchased by the Harrises for

less than $10,000 for rebuilding and resale. The Harrises sent us pictures taken during

the rebuilding, installed an 0-320 Lycoming, and then sent us pictures of the finished

product, for which they were asking $45,000. A little while later we got a call from

Valerie Harris saying we didn't have to worry about Merle Musson's Cozy any more. About 5

hours into the flight testing, her husband had an engine failure, landed in a muddy field,

flipped over, and pretty well totaled the airplane. He was relatively unhurt. The airplane

was insured, and the insurance company took it over.

In a recent Central States newsletter, it was reported that the insurance company determined that the gascolator was plugged with flakes of material identified at least in part as 2427 epoxy resin. We discussed this with Mike Melvill at RAF. He said they tested 2427 for compatibility with aviation fuel and found it to be unaffected. He agreed with me that if fuel did attack epoxy resin, it would do so only over a very long time frame, and would not end up in the gascolator as Flakes in such a short time. He said a more likely explanation was that there was construction debris left in the tank. He said they had an almost identical experience with an airplane they had built, and came to the conclusion that construction debris was left in the tank.

The thing to learn from this accident is that tanks should be thoroughly vacuumed before filling with fuel, and then the filter and/or gascolator should be repeatedly checked during the first few hours of operation (like it says in the Owners Manual).

- On Tuesday, October 8,1996, we received a call from Pat Young. Pat and his wife,

Jeannine, are friends of ours who have been flying a 3-place Cozy for a number of years,

and whom we have socialized with over the years at Sun 'n Fun, Copper State, and I think

also Oshkosh. They liked the 3-place so well, Pat bought plans for the Mark IV. We heard

that he had finished building and were anxiously awaiting word of his first flight.

Pat said he had bad news--he had crashed his airplane on the previous Friday, and had just returned home from the hospital. I was aghast, could hardly believe what he told me, but very grateful that he was still alive. Here, as accurately as I can remember, is what he told me.

He had about 14 hours on his airplane, and was still in the test period. He was solo, and had 25 Ibs. of lead ballast just ahead of the front seat. He said he calculated his c.g. to be at F.S. 100. He said it did not behave like his 3-place. He said that if he applied aft stick, it wanted to climb at an increasing rate and not return to level flight, as though there were a "balloon" attached to the nose (this sounded like it was unstable in pitch, which it shouldn't have been). Pat said he thought he might have an incidence problem with the canard (which would explain pitch instability), and had been changing the incidence of the main wing by adding washers under the incidence bolts to correct this tendency. Anyway, he had done stall tests without any apparent problem. On this particular day, he climbed to 10,000' and, without leveling out, purposely entered an accelerated stall. He said the canard stalled and the nose dropped. He thought he recovered by releasing stick pressure (normally it takes a lot of back stick pressure to stall the canard) to pick up speed. Then, he didn't remember what he did or what happened next, but the next thing he could remember was that the airspeed read zero, and the airplane was at about a 45 deg angle of attack. Using elevator, he could make the nose bob, but he couldn't get the nose down. He said the throttle had no effect, because the propeller was cavitating and not providing any thrust.

He had been 6,000' above the ground, and could not get the nose down. He hit the ground on the edge of a quarry. The right gear hit first, the strut broke in the middle (between the tabs) and the right leg departed the fuselage. The left gear hit next, breaking off the wheel and axle, and causing the airplane to roll to the right. When the right tip of the canard hit the ground, the canard was ripped off and the airplane cartwheeled and came to rest right side up. He thought he was semi-conscious, because a witness to the crash asked him to open the canopy, which he did, and helped him out. An ambulance was called and he was taken to the hospital. He suffered a fractured ankle, several broken ribs, a punctured lung, and it was still painful for him to talk several days later.

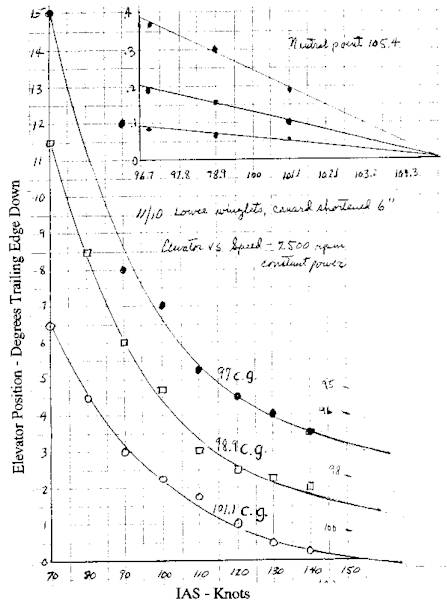

We learned in our flight test program that if the canard span was shortened 6" (first edition plans, blue cover) and lower winglets installed, our plans model Mark IV would not stall even 1.2" aft of the aft c.g. limit (F.S. 103.2). Pat affirmed that he had shortened the canard and installed lower winglets and was operating within the approved c.g. range. Searching for some explanation for what happened, I asked him what the position of his elevators was in fast cruise. He said, "trailing edge down about 4-1/2 deg." (he later said 3 to 3-1/2 deg.). This was a vital clue, because on our Mark IV in fast cruise and mid to aft c.g., the elevators are either in trail or very slightly reflexed (trailing edge up), and also indicated his canard incidence was too low.

After receiving this shocking news and having a chance to think about it, it didn't seem logical that a small error in setting the canard incidence, by itself, could account for what happened, and that there might have been other contributing factors. I told Pat I would like to come to Pueblo to try to figure out what caused his main wing stall. I then called the FAA and learned Mr. Jack Middleton of the Denver FAA and Mr. Arnold Scott of the Denver NTSB were handling this accident. I volunteered my assistance in investigating the accident and they accepted. They had already concluded that the wrong canard incidence might have been at least partially the cause. They said the airplane had been moved to Pat's hangar, where it was locked up, and they would need his permission to inspect it. They suggested we all meet with Pat in Pueblo as soon as it could be arranged.

We were finally able to meet in Pueblo on November 15th, about 6 weeks after the accident. Pat looked good, but he said his ribs still hurt a little. He had started rebuilding his airplane. We learned the following:

- Prior to the accident, Pat had removed 3 vortilons from the main wings to see if this would correct a yaw problem.

- He used an empty c.g. of 109 in calculating his c.g. at the time of the accident. The copy of his weight & balance on file with the FAA, which he submitted when his airplane was inspected, showed an empty c.g. of 112, three inches farther aft than the figure he was using.

- His airplane was not built according to plans and was not a Cozy Mark IV. <text

deleted per Nat Puffer> ....should not have been registered as a Cozy

Mark IV.

Our conclusion is that this deep-stall accident was caused by a combination of things which, taken separately, probably wouldn't have been a problem.

- Too low an angle of incidence on the canard caused pitch instability and let the canard reach a higher angle of attack than per design.

- Removal of 3 out of 6 vortilons on the main wing allowed the main wing to stall at a lower angle of attack than per design.

- A c.g. aft of the limit. Using his reported empty c.g. of 112, with his weight at 210 lbs., 25 Ibs. of lead under the instrument panel, and 25 gal. of fuel, we calculated that his c.g. would have been 102.34 in level flight.

- A power-on stall immediately following a climb to altitude would have allowed the fuel to shift aft resulting in a c.g. we calculated to be 103.1 (the aft limit for the Mark IV is 102).

- Failure to recover while he still had forward speed rendered his controls ineffective and allowed the stall to become locked in.

- This airplane was not a Cozy Mark IV. Our flight test results do not apply if the design is changed.

BUILDER DESIGN CHANGES

This accident could have been avoided. Pat put 14 hours on this airplane knowing that it was not flying right. If he had called us and told us about his elevator position in cruise, we could have told him either his c.g. was wrong, or his canard incidence was wrong, or both. He may have been reluctant to consult with us because he had made so many changes. We are sorry we were not allowed the opportunity to help prevent this accident.

A Cozy builder, who asked me not to divulge his name, told me that at Oshkosh he overheard other builders talking about some of the changes they were making. One said he didn't like the looks of the top of the elevators built per plans, so he filled in the top with micro to make them flat! First of all, the reverse curvature on the elevators is part of the canard airfoil, and very important to proper canard (and airplane) behavior. Secondly, adding that much micro will certainly make them trailing edge heavy and probably result in flutter, which in some designs can cause catastrophic failure of the airframe. He heard another builder talking about how he wasn't going to shorten his canard span as required for 1st edition builders. Another builder is installing an Infinity landing gear. He probably doesn't realize that in addition to compromising the structure, this gear will cause a pitch-down moment when it is lowered (like for landing), and a pitch-up moment when it is retracted (like in a climb out). Other builders are installing heavy engines which will give them an aft c.g. We are going to have a lot of builders in trouble if this keeps up!

Folks, we need to take airplane building more seriously. We have gone to a lot of effort and expense to try to make the Cozy Mark IV the safest possible design. If you build your airplane like our plans model, if it looks like our plans model, and if it flies like our plans model, you can call it a "Cozy Mark IV". But this airplane is an "experimental" airplane, and under the rules of this country, you have the freedom to make any changes you want. You can install the canard upside down, you can make a "stretched" version with 6 doors, you can buy someone else's modified pre-fab parts, or whatever. It's your money, your time, your life and the lives of your family or friends. But freedom carries with it a responsibility. If you change our design, you should not call it a "Cozy Mark IV". You can call it a "Whatzit", or a "Sidegrinder" or a "Mach 5", or an "Aerocanard", but not a "Cozy Mark IV". You'd better realize that you will be the test pilot of an unproved design. You really should install a moveable weight, like we did, so YOU can determine the acceptable c.g. range by changing the c.g. in flight, and you sure better do this above 10,000 ft, wearing a parachute, and be prepared to bail out, and make sure you can get out, if necessary.

We are very serious about this, folks! We are going to ask the FAA not to allow anyone to register his airplane as a Cozy if it was not built according to plans and does not look like a Cozy. We do not want our design to develop a bad reputation because of unapproved builder design changes. In some countries, for example Canada and Australia, you cannot get a homebuilt approved unless it has been built in exact accordance with an approved design. If you change the design, it is very possible you won't be able to get it approved.

If someone buys plans from us and is current in his newsletter subscription, we will provide builder support. If he has made changes in the design that we have not evaluated ourselves, we will still do our best to advise him. We have been involved in aviation for 53 years, and in the home-built movement and the EAA for 24 years, which is longer than most, and we have built and tested a number of different airplanes. We have a pretty good reputation (and are still alive). We hope builders will consider our advice to be valuable, but we cannot force them to ask for it.

MISINFORMATION ON INTERNET?

<Much text deleted per Nat Puffer>

We consider that it is our obligation to warn our builders about suppliers who don't meet our standards of trustworthiness and responsibility. If you choose to ignore our advice (some builders do), the decision is yours. But if YOU don't build according to plans, don't register it as a Cozy Mark IV.

COZY MARK IV OWNERS MANUAL CHANGES

Page 46, ENVELOPE EXPANSION: Add this:

Caution:

| Before expanding your flight envelope, you should make sure your airplane has positive pitch stability; i.e., if you trim it for level flight and then either pull back on the stick or push it forward, upon release of the stick, it should return to level flight in no more than 3 oscillations. Also, before expanding your flight envelope, you should double check that your canard is set at the right angle of incidence and/or your c.g. calculations are correct by comparing elevator position with the flight test data for our plans model shown below. If your elevator position differs by more than 1 degree, land and re-check your canard incidence using template "G", and re-check weight & balance and c.g. calculation. Do not fly until you have determined the problem and corrected it. |

|

- Page 19, Stall Characteristics, 2nd para.: After "shortening the canard span 6", add "to a resultant tip to tip span of 151".

- Page 19, Stall Characteristics, 3rd para.: Instead of "plans", substitute, "1st edition plans". Page 19, Stall Characteristics, end of 3rd para.: Add, "This applies to builders with 1st edition plans. The canard span has already been reduced on 2nd edition plans to 151" tip to tip.

- Page 25, under recommended entry speed for Stalls, after "Slow deceleration" add "from level flight only".

- Page 25: Delete "Accelerated Stalls" as an approved maneuver.

- Page 33, Canard incidence: Delete "templates B & C" (a holdover from the 3-place Owners Manual), and change to "template G".

- Page 33, Canard incidence: Change tolerance from +_ .3 deg. to + .6 deg and - .0 deg.

MARK IV CHANGES/CORRECTIONS

ACCIDENT PREVENTION

Quite by coincidence, I was invited to participate in a "Prototype Amateur-built Accident Investigation and Prevention Seminar" at the EAA headquarters in Oshkosh, WI, November 18 to 22. The seminar was sponsored by the DOT Safety Institute. The reason for this seminar was that experimental aircraft now comprise a significant portion of the GA fleet, which is getting larger each year, and the accident rate for experimental aircraft is higher than for factory built aircraft. The purpose was to bring together the designers of experimental aircraft with members of the FAA and NTSB to familiarize the latter with experimental aircraft designs and to discuss how we could all work together to better investigate and determine the causes of accidents and prevent them from recurring in the future. Ten designers and about 20 key FAA, NTSB, and EAA members were in attendance. I was asked to discuss canard designs and also any special problems related to building from plans vs. putting together a pre-fab kit. I was also asked to review any accidents we have helped to investigate.

We shared a number of common concerns. Experimental airplanes are involved in about 2 fatal accidents a month. About 85% of accidents are due to pilot error. A large number of accidents involve builder design changes and c.g. problems. The Cirrus people said they took their kits off the market (after selling 38) and are trying to buy them back because too many builders were making unauthorized engine installations, which resulted in aft c.g.s, and they already had had a couple of fatal stall-spin accidents. Everyone agreed that we didn't want more regulation, but that we needed to do a better job of accident prevention. The EAA has been very proactive in this area. As a result, Avemco offers a 10% reduction in premiums if a project is inspected at least 3 times by an EAA technical counselor. It offers another 10 % reduction if the builder belongs to and attends a local EAA chapter. And if the builder spends time with an EAA flight advisor and is deemed ready to fly, it will provide insurance during the first 10 hours of flight testing (the highest accident rate period).

FIRST FLIGHTS

- Glenn Pat Young, Pueblo CO first flew his airplane <text deleted per Nat Puffer> in September, but crashed it after 14 hours (see Accidents).

- Doug Solinger, Rochester MN first flew his 3-place on 9/3/96. He had 10 hours on it by 10/3/96, but hasn't sent us a report as yet.

- Randall Schoonover, Montgomery Village, MD sent us a real short note with a change of address on Sept 21 that his Cozy N72CR is flying well.

- Charles N Howell, Germantown TN flew into Copper State in his Cozy. We didn't get a chance to talk to him, and we don't know how long he has been flying.

- Bob Misterka, Grafton MA is flying and writes:

10/28/96

Dear Nat & ShirleyI'm sorry about being tardy with this report, but I'm sure you can understand that I've been pretty busy of late. I am happy to announce that my 3-place Cozy, N342RM made it's maiden flight at about 5 PM on 9/16/96. What a thrill!!

I had been doing high speed taxiing for a couple of weeks. I was trying to arrange an orientation in another Cozy, but for one reason or another was unable to do it. I was reluctant to fly without actually having done a landing in a Cozy, but finally decided to go for it. After doing a few more high speed taxi runs down the 5000' runway I felt comfortable enough with the handling to go for it. It was calm, the air was smooth and the traffic was light. It was the right time!

I lined her up on the end of the 5000' runway and pushed the throttle wide open. The 150 hp 0-320 quickly accelerated the airplane up to rotation speed and lift-occurred immediately thereafter. I had decided earlier to leave the nose gear down for this first flight and I was concerned with keeping the speed under control. Before I knew it I was doing 120 kts. So I pulled back some more on the stick and the Cozy climbed like a homesick angel. I was so excited that I didn't even think to look at the VSI so I don't know the climb rate (I've since confirmed it to be 1,500 to 2,000 fpm solo.).

The ground taxiing had pushed the temps up a bit and the climb out at full power pushed them up a bit more. I decided to level off at about 2,000' to let things cool down. I pulled the throttle back to about 1700 rpm and established a stable speed of 100 kts or so. I made a few circuits around the pattern to feel out the controls. The airplane was stable in roll and pitch and the trim was very good. The oil and CHTs stabilized.

I decided to try a landing. This was a first for me. My only experience in canard pushers has been a couple of hours in the back seat of a Long EZ. On downwind I reduced power and raised the nose to establish about 80 kts. I deployed the landing brake but it wouldn't stay down (it needed adjustment to accommodate the air pressure against it). So the rest of the approach was flown without it. The airplane did the base and final legs with a nice gentle 400 to 500 fpm descent. It felt like it was on rails. The landing and rollout was uneventful.

This flight was the culmination of about 15 years of dreaming. It started with a visit to a fly-in where I saw a Varieze and thought it was neat. Of course, I didn't have a pilots license.

I needed a private ticket and that followed when I had the money. Next was an 8-year building odyssey. What thrill to finally fly that airplane. I later told my wife that I was pleased that the project was no longer just an expensive planter, but a full fledged aeroplane (I'm sure she feels the same way too!).

Since then I have put on about 10 hours of flying around and checking things out. As expected, there are a couple of squawks that need attention, but overall things are okay. I need to improve the cooling of #3 cylinder. The CHT on #3 goes to 500 degrees quite rapidly in climb and is about 75 degrees higher than the others. The temps are good once they've stabilized in cruise. I've also got some work to do on the cabin heat system. There is also a small oil leak that I can't seem to pinpoint. So far, I have opened her up to 150 kts. Ultimately, once I get the prop fine tuned and some drag cleaned up I think we'll see 175 kts.

Nat, thanks for providing this wonderful design. It was fun to build and more fun to fly.

Bob Misterka

Grafton MA

EPOXY RESINS

We have heard an increasing number of complaints about poor peel strength with Epolite 2427, and sample layups sent to us by several builders did, in fact, have very poor peel strength. We checked with Mike Melvill, Rutan Aircraft Factory, which originally approved 2427. They have been receiving complaints as well, and agreed with our decision to remove it from the approved list. Wicks has also been receiving complaints and will no longer stock it. It seems that the 2427 originally approved, made by Hexcel, had acceptable peel strength, but after the manufacture was transferred to H.B. Fuller, the peel strength has gotten worse. Mike said that even though peel strength is not critically important in their and our designs, it would be better to switch to another epoxy with better properties. Here is a list of epoxies that have been and still are approved by RAF (and us):

Epoxy Kit Price (approx.)

----- -------------------

Aeropoxy 2032/3660(P[M&W) $53/ 1.0 gal

RAE 2426/2176 & 2177 69/ 1.25 gal

West 105/209 (Gougeon Bros) 79/ 1.20 gal

E Z Poxy (formerly Safe-t-Poxy) 83/ 1.25 gal

Proset 125/229 (Gougeon Bros) 110/ 1.25 gal

We have been using the original RAE system since 1976 on 5 different airplanes, from 3 different manufacturers (Lambert, Applied Plastics, and Hexcel), so it seems to be quite bulletproof. RAF says they consider the Proset to be the premium epoxy resin system, which they use on all of their airplanes, unless some other system is requested, but Mike said it is quite thin, so homebuilders might have trouble with it on vertical layups, and also it must be post-cured to obtain full strength. Of course, it is the most expensive. Be aware that each of these systems is a different ratio. The Gougeon resins and hardeners are available with their own pumps.

We have been monitoring both Sport Aviation or Kitplanes the last 3 months for pictures of Cozys, and found only one. It was Tim Merrill's Cozy Mark IV in the Oct. '96 issue of Kitplanes. Hope we haven't missed any others. Tim will get a complimentary renewal of his newsletter. We need more of you to send in write-ups and pictures of your finished Cozys to both Kitplanes and Sport Aviation. It doesn't matter if you have just finished, or have been flying for a few years. SEND IN THOSE PICTURES!

COZY BUILDERS HOSPITALITY LIST

Barbara Pershing publishes a "Cozy Builders Hospitality List". This is a list of Cozy people who are willing to extend their hospitality to other traveling Cozy people. The list is not to be used for commercial purposes. If you wish be on this list and to receive the most recent edition, please send any special comments and $2.00 (to cover printing and mailing costs) to Barbara Pershing, 8134 Buckridge Rd., Cedar Falls IA 50613.

FOR SALE

- Featherlite main landing gear strut for 3-place Cozy or Long EZ, $300 delivered in the US. (507) 437-6622.

- Cozy builder, Bill Walsh, has arranged a source of tee shirts (sweatshirts available on request) which come in various colors but only adult sizes. They have a detailed picture of the Cozy or Cozy Mk IV. The Cozy name is printed above. Bill is also working on other Cozy items, such as jackets, caps, pins, and cups. The shirts are available at $9.95 plus $1.50 shipping and handling. Orders for 2 or more are sent 2-day priority. Make checks out to Linda Walsh, PO Box 160884, Altamonte Springs FL 32716. (407) 695-3543.

- 3) Wayne Lanza makes a number of very nice goodies for the 3 and 4-place Cozys. He has an electric speed brake actuator kit with all the parts needed for installation, with instructions for $275. His latest creation is a switching and breaker panel for the Mark IV. It is similar, but not identical to the one we had made for our plans model. It is located at the top of the panel, which is the best location for appearance and access to the electrical system. Wayne is using the highest quality DC switches (they are hard to locate) and circuit breakers, and pre-wires the panels, making the rest of the electrical system installation very EZ. Cost is $425. We really appreciate Wayne's contribution, and heartily recommend his products to you. Contact him at: 9425 Honeysuckle Dr., Sebastian, FL 32976 (561) 664-9239.

- 4) We believe that the 4-pipe stainless steel exhaust system we designed and is being manufactured by Custom Aircraft Parts (see "Authorized Suppliers") is far superior to anything else available or advertised for the 3 and 4 place Cozy (or Long EZ, or any other pusher, for that matter). Cost is $500, which includes shipping and handling.

- New, improved fuel sight gauges. Clear bubble with white background. $35 per set. Vance Atkinson, 3604 Willomet Ct., Bedford, TX 76021-2431 (817) 354-8064.

- Dr. Curtis Smith's nosegear ratchet (which we recommend) is now priced at $40. Dr. Smith's new address is 1846 Sextant Drive, Worden, IL 62907-9631 (618) 656-8209.

- IO-360 A1A Lycoming 200 hp. Mid-time. Make offer. (602) 497-2365 after 6 PM mountain time.

BUILDER TELECON NEWS

- Richard Crapse, in Raleigh NC reported that he was flooded out by 4 to 5 ft. of water in the hurricane. He had his glass cloth stored in his fuselage tub (the boat stage). It floated and his glass cloth was undamaged.

- Val DeOliveira, in S. Floral Park NY reported that he was transporting his completed Mark IV to the airport in a truck, when the canard "took off", flew 15 ft in the air, landed on the freeway, and was run over by an 18 wheeler! He said one tip was smashed and the lift tabs were bent, but it was not crushed where it was run over. I asked if he could send me a picture. He decided to make a new canard rather than try to repair the damaged one.

LETTERS FROM BUILDERS

9/11/96

Dear Nat and Shirley,

Hi! It was nice to see you at Oshkosh again. Progress on my Mark IV is still behind my self imposed schedule, but it gave me a boost to see all the enthusiasm and energy at Oshkosh as well as some of the gorgeous planes on display. I thought Tim Merrill's plane was outstanding and look forward to reading about it in Sport Aviation, since he won the Grand Champion award. This is a great recognition of his work and obviously of your design effort.

Tim's engine/prop installation really got me thinking that if the CS prop can really deliver the performance (particularly in take off) that was quoted, it is very compelling, despite the cost. I've got a couple of years yet to make my engine choice, and its nice to see that there are some choices emerging.

I managed to take a couple of photos of the Speed Queen on my last day at Oshkosh. I'll reserve my comments and opinion on the design and the ethics of preselling it. Suffice to say, I'm pleased with the choices I've made to date.

Assuming I get to the US again, if it fits in with your schedule and its not a big

imposition, I'd love to go for a ride with you in your Cozy. Allan Aaron

Sydney, Australia

Editor: He did and we did.

10/20/96

Dear Nat,

This is my first status report on my Mark IV #565. A lot has happened since Dianne, my ten year old son Alex, and I bee lined into Oshkosh this year single-mindedly intent on buying a Velocity kit. We elbowed our way through the crowds, looking neither right nor left, straight to the Velocity demonstrator. But as soon as I sat in the plane I could feel the gentle hand of fate on my shoulder. The plane wasn't exactly like I had been imagining in my mind. We were a little disappointed and so we decided to procrastinate for a few hours. We wandered off to the flight line straight to the airplane of Todd Morgan and Kathy ? Kathy was kind enough to point us in the direction of more Velocities across the field, but not before we had been dazzled by the Cozy she and Todd were riding. Although we still didn't recognize it, Fate was intervening more strongly now. We crossed the field and ran into not more Velocities, but into Tim Merrill and his beautiful Cozy IV which was, at that very moment, being judged for eventual Plans-built Grand Champion. We stood gawking at this beauty, thoughts of the Velocity receding into the mists at the back of my brain. Tim and another Cozy builder, R. Randall of NYC, both took the time to explain the difference between the kit-built Velocity and the plans-built Cozy. Even a klutz could build one, they said. This struck a chord with me. So with little urging I headed off to find you and your display. When you explained the probable cost of the finished Cozy was less than what I was just an hour ago willing to pay for a lousy Velocity kit, I was sold! Do you take plastic? I asked. You smiled indulgently, said no, but a check would be nice. I smiled regretfully and said, sorry, the checkbook is in Baton Rouge where I inadvertently left in my rush out the door Oshkosh bound. You see fate's hand in this? How was I going to buy a Velocity kit with no check? Anyway, I promised the check for the plans would be in the mail as soon as I got home. It was and I ordered the Section 1 materials kit from Wicks the same day.

Since then we've re-worked the shop, converted and enclosed the carport as a large work area, and purchased lots of tools under Dianne's gimlet eye (are you sure you need that whichit?) An unexpected side benefit has occurred too—I've been liberated from the TV. Just hadn't realized how much of a habit it had become. Now I rarely think about it since I'm busy all the time in the shop. Best of all, both Dianne and I seem to be losing some weight which we need to do if we're eventually going to fly this bird.

So far we've done the three practice exercises and have built six of the seven bulkheads. The 2427 epoxy has worked great in spite of our south Louisiana heat and humidity. So far so good. Your plans are exceptional, Nat, and our hats are off to you. Even this here klutz can pretty well figure them out. I've also prepared a construction plan using some project management software to keep a record of what we did when and how long it took. I'll try to use it as a lookahead and work plan too.

Anyway, that's it for now. We'll keep you posted on progress and will send some pictures too. Our door is always open if you're ever in the area, so please, please, come by if you can. Your new Louisiana friends and builders,

Todd, Dianne & J Alex McLean

(565 for short)

Baton Rouge, LA

Editor: Thanks for the invite, Alex. Baton Rouge is one of our favorite fuel stops on our way to and from Sun 'n Fun.

10/30/96

Dear Nat,

Thank you very much for providing plans for an aircraft that is fast, affordable, and can carry four people. It is to your credit that you test all changes before recommending them to your builders. I also wanted to thank you for meeting me at the airport and showing me your airplane the night before you left on vacation last January. It impressed me very much that you would inconvenience yourself so much to show your airplane to a builder.

I had a great time at Oshkosh this year. The Cozy dinner was wonderful. It is so nice to meet people from around the world that share a passion. Congratulations on having two Cozys win grand champion plans built. You must be very proud. I know I am. Once again thank you very much for everything you've done to further the homebuilt movement.

Steve J. Miles

St. Charles, MO

11/5/96

Dear Nat,

Please renew my newsletter. I thoroughly enjoy reading it as soon as it is out of the mailbox. I do have one question - and I hope you will make an honest assessment of this in the newsletter. First, I think Tim Merrill's Cozy, as shown in Sport Aviation, is truly an outstanding airplane. Certainly workmanship well deserving of a Grand Champion. My question is, how can a plans-built airplane be a "Grand Champion" when it is built so far off of what the plans call for? 27% heavier than the prototype certainly reduces the overall utility that the plane was designed to have. Thanks for all your work and effort to keep the public informed.

Marvin Royster

Doraville, GA

Editor: Good question. The judges are basically judging beauty and workmanship, and that's where Tim's Cozy has it in spades. There is no way they can determine how well a given aircraft performs. In Tim Merrill's defense, with only an 0-320 but a constant speed prop, he can develop more hp for takeoff than I can with a Franklin engine (which also makes my Cozy overweight), and he can increase his gross for that reason.

10/29/96

Dear Nat & Shirley,

This is a letter I'd planned to send last spring, but life got a little out of hand. I found myself changing career paths when my ex-employer ran afoul of the IRS and I got an offer to become an aircraft mechanic. It's quite a change from desktop publishing, and I really enjoy the work. The best part is that it dove tails with my plans to get my A&P license, something I've been thinking about for years. The bad part is that I now work nights. All of this happened just before Arlington, so I missed it as well as the Westlunds barbecue.

I was pleased to read in US Aviator that you'd gotten the Franklin engine installed. I also read in Sport Aviation that the Grand Champion Plans Built was a Cozy Mark IV. I'd like to say that I've been zooming along on my own Mark IV, but it's been on the back burner since spring. I won't be able to devote any real time to it until I finish school. Thanks for a great airplane.

Rick Faktor

Tacoma WA

10/29/96

Dear Nat and Shirley,

I've been working on my Cozy Mark IV for a year and seven months and wanted to let you know the progress I've been making. The airframe is complete, and it is filled and primed, awaiting paint. The engine installed is an 0-360 with high compression pistons, 0 timed. All of the instrumentation has been installed and I am awaiting the arrival of my prop so that I can start my engine and begin taxiing! The project has been going very smoothly, due to the high quality plans that I received from you. Enclosed is money for a renewal. Hope to see you at Sun 'n Fun '97.

Christopher Scida

Rocky Point NY

10/14/96

Dear Nat & Shirley,

Please send me one set of Cozy MK IV plans (check enclosed). I might as well stop postponing the inevitable. I've sat in Steve Blank's project, saw David Higgins beautiful Cozy at VRB last weekend, flew in a Velocity, read almost everything possible on the subject, and spoke with you. I am looking forward to receiving the plans.

Don Rothrock

Port St. Lucie, FL

Dear Nat,

Please renew my newsletter. I am a US Marine in VMFA-314, which is a F/A-18C fighter squadron, soon to deploy on the USS Nimitz. Unfortunately, carrier qualifications keep us very busy and the commute between LA, where I live, and San Diego, where I work, eats up another 4 hrs of the day. This leaves me with only a few minutes per day to do work on Cozy #352, but it is coming along. Hopefully, I will have her completed by the time I retire.

James Callahan

Whittier, CA

10/8/96

Dear Nat,

Enclosed is a check for newsletter renewal to keep your outstanding newsletter coming awhile longer.

My Cozy Mark IV project is progressing slowly but surely. I have completed the fuselage assembly and have started on the bottom. It seems that I have run out of space in my shop and I am sort of in a dilemma. I'm either going to have to build a new garage on my house, or buy a new house with a garage. One piece of good news is that after a 14 month wait, I finally received my reserved tail number from the FAA. Kris and I really missed going to Oshkosh this year. We had a blast last year, especially at the banquet and forum. I was out on Johnston Island and I couldn't get off from work. Hopefully, we will be there next year. Thank you for your remarkable builder support and a great set of plans!

Lee Dillingham

Rock Hill, SC

10/6/96

Dear Nat and Shirley,

Greetings! Enclosed is a check to catch up on the newsletters. I'm between Chaps 4 & 5 currently and have loved every bit of it! I can't wait until it starts looking like a fuselage. I plan on following the plans exactly, simply because you have taken all of the guesswork out already through extensive testing. I am seriously considering the Franklin engine, though. I have been following your testing rather closely, and the E mail group that Marc Zeitlin has, has also been beneficial.

Happy flying! Aim High! (from us Air Force guys).

Chris Sawyer

Vandenberg AFB

9/28/96

Dear Nat & Shirley,

It was a pleasure to meet and talk with Shirley at Oshkosh. Nat was with a potential customer at the time and my two daughters were anxious to move on and see all the sights. Our intention was to stop by later after the air show, meet Nat and maybe sit in your Cozy. As you may recall, that was the day the storm rolled in about 5 p.m. and it was an all out mad dash for the car. I glanced over at N14CZ as we were going down the walkway but didn't see anyone around. What a disappointment not to meet Nat. Our trip to Oshkosh was part of a week long family camping trip and we had only planned for a one day stop. The following morning we had to leave for the upper peninsula of Michigan to friends for dinner.

I'm now into chap. 9 and was completing one construction chapter a month until this point, but the past four weekends have been filled with other obligations, so I'm giving myself an extra month on this one. It should be completed by Octobers end.

Hope to get the chance to meet both of you in the near future.

Craig Pornaville

Utica, MI

9/20/96

Dear Nat,

Progress on my Mk IV #494 continues to go well. The fuselage, canard, main spar, canopy and controls are done. I plan to complete the wings and strakes this year, and the engine, avionics and paint by next fall. I'm having lots of fun building, but can't wait to be flying. If you know about any good deals on a Lycoming 0-360 engine please let me know, because I need to get one within the next few months.

I am including two pictures; one of my two girls puke and Jennifer), and the other of me in the pilots seat. Both pictures were taken last June, so I'm farther along now.

Mark Beduhn

Greenbrier, AR

9/15/96

Hi Nat & Shirley,

Just a few notes regarding newsletter #55. I'm not sure my publicity pictures have been given credit for the complimentary newsletter renewal. (Editor: Duly noted and corrected.)

Darryl and I are planning to attend Copper State this year. We have already made arrangements for lodging at the Days Inn. It is our intention to make the Cozy dinner Friday night. We appreciate your kind offer of lodging and transportation. But please feel free to grant the opportunity to others.

My continued admiration for your leadership and the responsibilities you bear. You have taken commendable positions through the years. Please know that your Cozy builders value you knowledge and opinions.

Chuck Wolcott

Simi Valley, CA

9/20/96

Dear Nat,

You were kind enough to make time to give me a ride two springs ago when I was out your way to hike the Grand Canyon, and I still remember vividly how well the Cozy flew and how beautiful the Phoenix area looked from the air. Unfortunately, I'm still waiting for my fiancee to finish graduate school, and that has put home buying and plane building on hold. Thanks for a great newsletter. Enclosed is a check for renewal.

Michael Nolan

Rock Island, IL

9/15/96

Dear Nat & Shirley,

My Mark IV is coming along very well. My fuselage is done. It is on the gear, front and rear with all interior components installed as well as all the controls. The canopy is also complete with windows and latches and is on the fuselage. The center section spar is installed and the strakes are nearly complete. Both wings are done. The only structure I have left to build are the canard and the winglets. I have already purchased my exhaust system and engine mount and am very impressed with the workmanship. I have just purchased an 0-360 A3E for $8,000. It has 1274 hrs since new. I purchased all of my instruments from Howard Francis (newsletter #42) in Tempe AZ and will give the quality of his work a very strong endorsement. I will see you again at Sun 'n Fun, where I plan to buy all of my avionics. Maybe I will fly my Cozy to Oshkosh '97 (I think I said that about '96 too). Please renew my newsletter.

Gary Dwinal

Lisbon, Maine

9/24/96

Dear Nat,

Quite a time now since I send you some news. I felt it necessary today. First of all, congratulations on the wonderful scoring done at Oshkosh by COZY builders. You deserve it, Nat, as much as the builders, by your great design and support. No question about it, you help a lot getting those outstandings.

Now let me update what is going on in our area. The Cozy group in France is building up quite fast in the Paris area. We are 6 now.

-Gilles Desgruelles, Cozy 3 flying

-Yves Pranal, building a Cozy classic.

-Alain Raposo, building a Mark IV.

-Jean-Pierre Portehaut, building a Mark IV.

-Bernard Cannac just starting now a Mark IV.

-myself, Benoit Lecoq finishing a Mark IV.

We are meeting fairly often and sharing orders. Exchanges work quite fine and it is very nice.

Now about my progress, the structure is nearly finished except for linking winglets to wings for storage space reasons. I am waiting the very end of the project because wing with winglet takes a lot more space in the garage. Apart from that, I finished the fuel strokes including the leak test. I am happy to say the there was not one leak. Yes, None! You could understand I was quite happy with that. At the beginning of the test I found I had leaks on both sides, but the leak rates were the same, so I started questioning about my test set up and indeed the bike tire valve I was using to inflate the tank was leaking. So I changed everything and started by testing the test set up alone first and from there everything was fine. I suggest that you pass on to other builders because doing that first hand would have saved me a few wondering days.

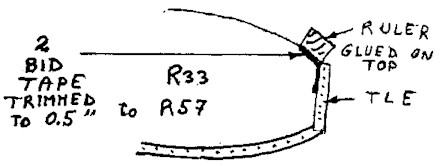

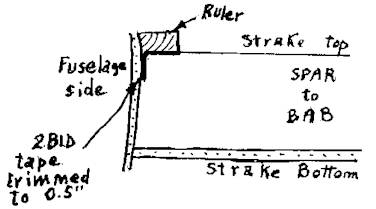

I have a trick that could help other builders to get that same result. Before closing

the top strake skin, I added a small 90 deg. tape at the top of TLE inside the fuel tank

(not necessary on the luggage compartment part) and also between the spar and BAB. This is

done by gluing a ruler on top of these and taping a 2 BID below. After cure you remove the

ruler, sand and trim to 0.5". This behaves like a tape and allows to keep more flax

at the junction of the leading edge and aside the top along the fuselage where it would in

the other case slide along it when doing the closing. The weight addition is nothing

compared to the flax saving when closing the strake.

The engine cowlings from Featherlite were then matched perfectly without any problem. Think about it. I had to sand less than 0.1" of the cowling along the wings to get the match. Again your design!!!! I am now in the finishing process which I started on the bottom of the fuselage at the same time I was doing the glassing of the strakes bottom (to save the number of flip overs which have to be scheduled ahead). In fact, I sometimes ask help to flip over the fuselage. It needs 6 to 7 friends or relatives, so we prepare a nice drink party (with French wines), call up friends. 15 minutes to flip over the fuselage, and a drink party then on!!!

I also want to point out about one thing that worries me a bit. I am reading and hearing a lot about guys willing to cut the lower winglet, have a retractable main gear, and so on. As an airline pilot who is security and flight safety minded, please, please, point out that an accident is always, always is made of little individual occurrences that alone would not be a problem, but on the bad day those things would add up very sadly to create an accident. Our job is to detect those tiny things one at a time as much as possible and remove them right away. But, as a human being, we have to admit that some of the tiny mistakes will be hiding sometime even for the best pilot ever. A few examples:

-The lower winglet. Alone yes it can improve performance to remove it, but the day you are leaving for a long flight with a heavy passenger at the back, while hot air, while tired by a nice dinner the previous day, while weather is not so good, while c.g. is too far back....Do you want me to go on? No, I guess.

-Retractable gear. One day a friend told me. You airline pilots never forget to extend gears. I reply very strongly by a very loud No, No!!! and on our airliners we have a lot of warnings to remind us our mistake, not to mention the Ground Proximity Warning System which I do not think can be set up on a small airplane. To me it is useless to retract the main on our Cozy. It means less fuel, more weight, more mistakes, not to mention more building time for a slim speed increase.

In our world we say, "there are bold pilots and old pilots, but no old, bold

pilots". We always have to ask the question: Am I doing the right thing?

We are building our reputation ourselves. Regulations are changing a lot right now. Let us convince our administration to go our way, not "Murphy's law" way (i.e. strong and limiting for us). What are your feelings about that? There are some new designs shown in Oshkosh prior to flight testing. Berkut or E-racer do not have lower winglets. Looking forward to your reply and again, thanks a lot for your design.

Benoit Lecoq,

Paris, France

Editor: Benoit, thank you for your thoughtful letter. I agree with everything you say. I feel badly about those who set a poor example for others. Unfortunately, there are some builders who are unwilling to learn from the experience of others, and are destined to have to learn from their own experience.

9/27/96

Dear Nat & Shirley

The airframe for our 3-place Cozy is complete and the finishing is nearly done. It has taken us about 6 months, but everyone says we're doing a great job. We had a couple problems during the last stages of construction which I thought I'd mention.

We had a major setback when we pressure-tested our strakes. When we neared 1 psi, we were startled by a very loud BOOM! We relieved the pressure and investigated. The center baffle had debonded from the mating upper strake skin. This happened because we waited too long between an application of a wet, sealer coat of epoxy on the inner strake skin, and a second application of epoxy just before installing the stroke tops to the flexed baffles. I noticed at the time of the second epoxy coat that the skin surface was tack-free, but assumed it was still "chemically sticky". It had only been an hour or so between coats, but it was a warm day. The de-bond occurred between the layers of epoxy. When we cut the strakes open, I could peel out most of the second layer of epoxy as if I were pulling off old shelf paper. I used a single-edged razor blade to get the rest. After repair, they tested fine. From now on I will prepare tackfree surfaces with sandpaper.

A less serious problem occurred when using pour foam to make the fairings that tie the forward face of the firewall into the fuselage. We were pleased with the results, until the next day. What had been a very smooth, well contoured, well-skinned surface the night before somehow deformed during the night into a mass of bumps and dips. My best guess is that the cold and humidity "soaked" into the raw foam--I was working outdoors on a chilly evening--and that use of the hair dryer to wet out the layups created some thermal anomalies which got worse as the layup cooled and cured. And since the foam density of pour foam is not very uniform, collapsing air pockets may have contributed to the effect we observed.

Our pour foam experience convinced us to take a different approach with the NACA inlet scoop on the fuselage bottom. Using the full-size drawings and the depth dimensions in the plans, Mike made a pair of hot-wiring templates from thin aluminum, and we cut a single piece out of blue Styrofoam. Then we cut the single piece in half lengthwise to make the mirror image halves. A little cut-and-fit around the gear legs--and voile! We faired them in using long sanding splines to get very sharp corners, a nice flat, uniform surface--and best of all, a good glass job. We recommend this method to anyone who hasn't yet built the scoop.

We got our overhauled engine back from Lycon (a well known shop in S. Cal) yesterday, and will begin the installation adventure in a couple weeks. We've also bought most of our flight instruments, but not our radios. A friend at work often receives catalogs from vendors selling pre-wired electrical harnesses for all kinds of aircraft, including homebuilt. We're going to explore that option. Very soon we also expect to order the exhaust pipes, the prop, and Wayne's breaker panel.

Finally, I have a builder hint for the hi-tech crowd. We had to reset our wheel axles, and we used the Cozy method to do it, which involves sighting through a tube held against the end of the axle. It occurred to Mike after we'd finished that for pinpoint accuracy the ideal tool for this job would be a laser pointer, in place of the sight-tube. Of course, you need to own a laser pointer, but, like I said, it's for the hi-tech crowd.

Thanks for your assistance and hospitality these past six years. The light at the end of the tunnel is getting brighter all the time.

Liese & Mike Brown,

Torrance, CA

10/1/96

Dear Nat,

I'm moving like a turtle with an anchor on Mark IV #466. Young children and a business of my own leaves little time for sustained work. I am getting ready to glass the bottom of the fuselage. The Cozy Internet group has been very helpful as well as Ken Brimmer who gave me a ride in his Cozy this spring. I'm someone who is in the "people" business (psychotherapist) and I purchased plans and started my project without the benefit of having flown in one first. Ken showed me my trust in you and the Cozy has certainly not been mislaid. I felt as if I was going 150 kts in a bathtub for all the visibility. I had not lost any of my resolve to build, but when Ken graciously demonstrated the famed stall (anti-stall) characteristics for me I practically ran home with a renewed burst of energy for my little foam block. It is a little strange the support I have received from the neighborhood. Half think I'm a nut. (You're building what?) The other half keep wanting to come over and get disappointed when I don't have more work finished. The important thing is my wife and my family behind me. My brother in law is an Air Force F-15 pilot with almost 20 years. He is excited about the project and asks about it often. I couldn't imagine him being excited about this with the type of flying he is used to. He retires (to the airlines) next year and is starting to think about building himself. He would be an easy convert but I would have to work on my sister to have her OK. Lt. Col. is still outranked by Wife. My brother became interested in building a Long EZ way back in '76 and never did. He lives next to Wicks and has been my parts liaison. I am resolved #466 is going to make it to the completion pages of Kitplanes and this publication. Renew me for 2 more years please and I will continue to look forward to each edition.

William Hixson

Poolesville, MD

9/29/96

Dear Nat,

As usual I have let another year pass and my newsletter subscription is past due. Also notice my new address.

Another year has passed, but not without some progress. From the enclosed pictures you can see that my Cozy is at Addington Field and assembled. I have run the engine enough to check for leaks, static rpm, etc. There are just the final details and the weight and balance left. I consider myself a full year behind schedule, but I can accept it easily enough. My plans number is #173 so I don't think that too many builders have charged ahead of me. I will give you prompt notice when the first flight is behind me.

Mike Davis

Leitchfield, KY

10/1/96

Dear Nat,

Progress on my Cozy was interrupted briefly by my move to Wyoming. I have purchased a hangar and resumed construction. I am at the finishing stage--what a job its turning out to be. I've found if you mix your micro like biscuit dough, you can get it to form a good "micro putty" as dry as you like. I do this by getting the micro dry as possible in the cup--then transferring it to a flat surface and cutting in microballoons with a small spreader. Then I use a triangle trowel to spread the micro on, and then a plastic spreader to smooth it out.

Rick LaCourse

Worland WY

10/2/96

Dear Nat,

How time does fly. Progress on my Cozy III #466 has been very slow the last 2 years. Hope to make better progress this winter and spring. Am presently on the canard. Thanks again for the design and plans.

L.G. Smalley

Geneva, IL

9/22/96

Dear Nat & Shirley

We met you at Oshkosh on Sunday. I tried your front seat on for size. My chunky 6'2", 240 lb. body fit just fine, which was a relief since I was already building. Good thing my wife weighs in at less than half of what I do.

I'm currently working on the canard, attaching the end pieces to the main portion. I expect to skin it this week. Then on to the elevators. Everything is going as well as expected. I have not encountered any problems I couldn't either solve or get help with. Will mail some pictures soon. Take care.

Larry & Steph Jansch

Flower Mound TX

9/22/96

Dear Nat,

Your work and reports on the Franklin engine are very much appreciated. After a long pause on my Mk IV #113, I'm back on my project in full swing. I hope this enthusiasm continues through completion. A close friend (Bob Misterka of Grafton, MA) recently flew his Cozy for the first time on September 16th. All went well without incident and he's elated. This close contact with a Cozy will certainly bolster my efforts to finish my Mk IV.

Tom Riley Westport MA

9/18/96

Dear Nat,

We had a great time at Oshkosh '96 and especially at the Cozy banquet. We made fast friends with the Bradleys, Pat and Vera, at the banquet. We accepted their invitation to spend a night at their place and see their Cozy IV project on the way home to Texas. It was only a couple of hundred miles out of the way, they live in Iowa, but it was well worth it. I'm always impressed by the ingenuity displayed by Cozy builders, but I think Pat is in a class by himself. I can't wait to see his project finished. It's really going to be an eye popper.

I bought an engine (for my 3-place Cozy) in Arkansas on the way home. It's a run-out 1969 Lycoming 0-320-E2A. I bolted it to the airplane and now the real fun begins. It's mounted on a heavy duty 0-320 Brock mount. I've enclosed a few pictures. In order to make it fit, I had to temporarily remove the right Bendix magneto switch cap. It would have extended 0.2" into the firewall. (Editor: I advised Will to replace the Bendix with the smaller Slick)

Thanks again for making it possible for all of us builders to be on this fun Cozy adventure. It's been fairly simple and straight forward so far, but I suspect it will start to be more complicated with the engine installation and maybe even more fun.

Will Sladaritz

Beaumont, TX

10/15/96

Hi Nat,

The revised design of the nose-lift system is complete, and the complete kit with drawings should be ready to ship the last week of October. Pat Reina allowed us to use his Cozy to proof the prototype.

We used Tom Ellis' basic design and modified it to handle heavier loads. It will now lift a fueled Cozy with luggage and one front seat passenger. It is a bolt-in retrofit for all EZ type aircraft and the first 25 kits will be priced at $750 ea. It is a very compact unit, weighing only 8 Ibs. more than the unit it replaces, and has a manual override. I have committed to a production run of 100 linear actuators, which I can sell separately for $285 ea.

For more information or an order form, call (615) 373-8764 or (615) 373-9707.

Steve Wright

Brentwood, TN

11/18/96

Dear Nat,

I would like to share with other Cozy MK IV builders my experience with the weight and balance of my own MK IV. First of all, it is imperative that the procedure be done correctly and re-checked for accuracy. You will also need at least one helper. I first tried to do this procedure with what turned out to be the wrong kind of aircraft scales. They were of the load cell type that are placed on top of an aircraft floor jack and connected to a central wt-readout module. These are fine scales for a Piper or Cessna that has known jack points, but you are guessing on the exact scale location on a Cozy because you can't plumb bob it's location once the jacks are in place to weigh a Cozy. This problem continues because you must use wide area jack supports under the plane to avoid the load cells and jacks from punching through the wings and fuselage. These inaccuracies led me to miscalculate my wt & teal computations giving me an empty weight c.g. of 2 inches aft of what the flight manual allows. To correct for this I added additional ballast to bring the empty c.g. to a more forward location, which in turn made my airplane rotate slower on take off (see where this is headed?) and fly rather nose heavy. The whole point is that my airplane wasn't at an aft empty c.g. in the first place. I only thought it was, which caused me to use extra ballast that I didn't need. All caused by bad weight points.

The second try was done because I found I was flying around with slight trailing edge down elevators and the nose felt heavy all the time. I wanted to find out why. This time I used flat scales borrowed from my local EAA chapter and I built wood ramps to run the airplane up on to the scales. Not only did I feel safer using this method as opposed to jacking, but it was much easier and allowed me to re-check my reading for verification. My Cozy flies great now because I was able to take out 25 Ibs. of ballast that I didn't need and I feel better to boot. Realize that the FAA is looking over our shoulders and in light of recent events we need to be ever attentive to detail.

Some hints: Do this in a hangar with the doors closed, as any wind at all can affect your readings. Use a digital level if possible. Use a chalk line on the floor and your builders straight edge to translate your plumb bob positions to the center line. Remember that the wing leading edge F.S. 113.9 is established and all other readings are taken from there. In other words, set your tape measure to 113.9 and set that measurement onto the translated wing leading edge point. It then becomes easy to measure off all the other translated points. Then compute your wt & teal. Be sure to follow the description in the Owners Manual and study the examples and you shouldn't have any problems. Blue skies and tail winds to you.

Franz & Terri Bibbee

Cozy N68TF

11/18/96

Dear Fellow Builders,

A plea for restraint. Having been involved with composite homebuilts since 1986 with my own Long EZ and a number of other designs during a period of years spent in the US working in composites research, I have become worried by the cavalier approach some builders are taking towards major structure considerations and the subsequent publishing of these "discoveries" on the Internet (like hard shelling). I am the first to concede that in the course of building your project you're bound to discover the best technique for you; that's the way of life in developing new skills, but when it comes to behaving as an organic chemist or materials scientist surely that's for the qualified, not the enthusiastic amateur.

Having purchased ones plans from Co-Z Dev. or wherever, you're buying into a whole bunch of expertise both engineering and aviation from Burt Rutan, Nat Puffer, et al. Why then choose to ignore it and spend valuable building time experimenting with your life, then compound the danger by advising the novice builder to follow your risky experiment? Experienced builder/flyers bear a special responsibility here because of the reverence and kudos that the novice attaches to those who have done it before. So please behave responsibly, restrict your ideas to the genuine advancement of building safety and pleasure for you and others and let the Canard Pusher or Cozy newsletters be the medium for transmission where the questioning/experienced/critical opinions have a chance to comment. People's lives my depend on it! Happy building!

Debbie Jones, M.SC.F.R.A.M.

Composites Design & Analysis

Cheshire, England

11/11/96

Dear Mr. Puffer,

I have spent eight months studying and comparing homebuilt aircraft designs and have looked at several in various stages of completion. After two trips to Elizabethtown to see Mike Davis and his nearly completed Cozy Mark IV, I was convinced. I am now ready to "take the plunge". Enclosed is my check. Please send me the plans so I can get started.

Marion F White

Perryville, KY

11/14/96

Dear Mr. Puffer,

I've decided to do it! Please send me plans and construction manuals for the Cozy Mark IV.

I am the US Border Patrol pilot with whom you have talked on the telephone a few times. I thank you for your patience in answering my questions and for faxing me the information I requested. After attempting every possible way to maneuver a cutout drawing of the fuselage through a scale 9' wide garage door, I have concluded that I will just have to modify the house before I begin construction. Thankfully I have discovered that this will be a very simple task. Since I never ordered an info pack, please include one with my plans. Many thanks,

Chase Snodgrass

Laredo, TX

10/26/96

Dear Nat,

Enclosed is product information on the Allegro engine monitor we manufacture. I have 250 hours on the gauge in my Cozy 3-place. It has been a real asset in many ways, including fuel savings through accurate leaning, and trouble shooting many minor problems, like plugged fuel injectors and a loose exhaust stack that could have ruined my whole day. The gauge has built in fuel flow available at a fraction of the cost of many stand alone systems, and we offer a 2-year or 1000 hr. warranty on the system.

I will be available on a part time basis to build Cozy parts to plans and configuration. Feel free to post this in your newsletter if you wish.

Sincerely,

Robin duBois

Allegro Avionics

1332 E. Hampton,

Tucson AZ 85719

(520) 327-3695 Fax(520) 327 0426

Editor: Robin is a good builder whom we have known for years.