Belleville Washer Application Experiments

[ Up ] [ Belleville Washers - Part 1 ] [ Belleville Washers - Part 2 ] [ Belleville Washers - Part 3 ] [ Belleville Washers - Part 4 ]

After the one hour of test flying the airplane last week to ensure

that the wing/winglet repairs were OK and that the engine still works,

I collected all the belleville washer hardware and associated

paraphernalia I had purchased. I wanted to start characterizing their

behavior and utility for the task at hand, namely ensuring a robust

propeller bolt retention system that's far less sensitive to propeller

hub expansion/shrinkage, and one that requires far fewer torque checks

(like, NONE) and far less human interaction, and what human

interaction there would be, would be simple, easy and fast.I purchased 7" prop bolts from

Saber - 1" longer than the standard 6"

bolts used with the Hertzler propeller. This would afford room for

the two AN970-8 wide area washers, as well as either four or six of

the bellevilles.

- First, I verified that even if I bottomed out the bellevilles,

I would not bottom the threads of the 7" bolts on the

extension lugs. This ensures that I can always maintain tension on

the bolts/bellevilles.

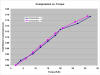

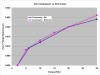

- I then performed a series of deflection and compression vs.

turns/torque experiments to try to determine the linearity of the

stack of six belleville washers captured between two AN970-8 wide area washer.

Suffice it to say that the bellevilles

were VERY linear with respect to both torque, compression force, and

number of bolt turns to achieve both. This kind of data is about as good

as it gets for small data sets :-).

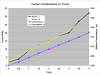

- I also wanted to compare the 6-stack of bellevilles to the hub

compression achieved by normal bolt installation. As it turned out, I could achieve exactly the

same hub compression that Gary Hertzler says we should get (~0.006

in./in. of hub thickness) with either the standard bolt installation

or with the 6-stack of bellevilles between the two wide area washers under

the bolt head. Not only that, but the hub compression was obtained at

essentially the same bolt torque as well - an average of 30 ft-lb. I installed

all six bolts with the 6-stack of belleville washers to ensure consistency.

|

|

|

|

|

|

|

|

Propeller Hub Compression vs. Bolt Torque (Standard Bolt Installation vs. Belleville Washers) |

|

|

|

|

|

|

|

|

|

|

|

|

Washer and Hub Compressions, Bolt Torque vs. Bolt Turns |

|

|

|

|

|

|

|

|

|

|

|

|

Hub and Washer Compression vs. Bolt Torque |

|

|

|

|

|

|

|

|

|

The main difference between the standard bolt installation and the

belleville installation was that the standard bolts required 1/2 turn

to go from essentially 0 torque to 30 ft-lb. This is 60 ft-lb/turn,

or 10 ft-lb/60 degrees, which happens to be one "flat" on the bolt

head. The belleville installation required between 4 - 5 full bolt

turns to reach the same torque levels - at 30 ft-lb/4 turns, that's

7.5 ft-lb/turn, or 1.25 ft-lb/60 degrees - far lower sensitivity to

amount of rotation.

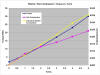

- With the standard installation, losing 0.013" of hub thickness due to

shrinkage would lose ~1/2 of the compressive force and therefore ~1/2

of the friction force between the hub and the prop extension. A

growth of the hub due to expansion would INCREASE the compressive

force by ~50% (and possibly crush the wood).

|

|

|

|

|

|

|

|

Hub Compression Force Loss vs. Hub Shrinkage (computed) |

|

|

|

|

|

|

|

Given the linearity and compression of the belleville washers, losing

0.013" of hub thickness due to hub shrinkage would lose between 6% -

8% of the compressive force in the configuration in which I've got them. An

increase in hub thickness due to expansion of 0.013" would increase

the compressive force by the same 6% - 8%. Both of these are probably

within the noise level for our ability to measure torque levels.

OK - so far, so good, at least in theory.

See "Belleville Washers - Part 2" for what the installation looks like on

the propeller hub.

[ Up ] [ Belleville Washers - Part 1 ] [ Belleville Washers - Part 2 ] [ Belleville Washers - Part 3 ] [ Belleville Washers - Part 4 ]

Return to: Cozy MKIV Information

Copyright © 2007, 2008 All Rights Reserved, Marc

J. Zeitlin

e-mail: marc_zeitlin@alum.mit.edu

Last updated:

May 18, 2008